Monitoring surface settlement for safe operations at China’s Guangzhou Baiyun International Airport

By: Li Wang, Peng Xiangdong, Product Application Solutions Division; Megan Hansen

When an airport expansion project in southern China met geotechnical challenges and the risk of surface settlement, they needed a solution to monitor the situation while keeping operations safely running. The solution? Installing a customised, automated Leica Geosystems monitoring system that enabled contractors to track surface movements in real time without disrupting airport activities, safeguarding infrastructure and passengers.

Expanding one of the world’s busiest airports

Guangzhou Baiyun International Airport, located in the thriving capital of Guangdong Province, serves as one of the world’s busiest aviation hubs. Spanning over 1.18 million square metres across two terminals. The airport recently opened its fourth operational runway to accommodate growing demand - by 2030, annual passenger numbers are projected to reach 120 million, with cargo throughput expected to exceed 3.8 million tons. To support this growth, the airport has embarked on expansion projects, including the addition of new runways and a third terminal. However, beneath the surface lies a significant challenge: the limestone bedrock, with fissures and karst caves, presents a risk of land subsidence during construction. Ensuring safety during the expansion requires continuous monitoring of surface settlement above the tunnels under the runway – a complex task in a dynamic airport environment. By implementing a tailored Leica Geosystems monitoring solution, contractors gained real-time insights into surface movements, enabling safe construction progress without disrupting airport operations.

Monitoring in a complex environment

Monitoring ground movement at a busy international airport presents unique technical and logistical challenges. Achieving millimetre-level accuracy and continuous measurements to detect even the slightest surface shifts required a highly specialized approach.

Observation points near the runways were limited, and the monitoring equipment had to adhere to strict height restrictions of no more than two metres to avoid interfering with airport operations. Traditional methods, such as installing prisms, were impractical on active runways and the system needed to operate autonomously, as prolonged human presence in these areas was unsafe.

To meet these requirements, the monitoring setup had to function independently of external power sources while reliably transmitting data for real-time analysis.

A specialised monitoring system for a dynamic site

To meet the project’s unique challenges while ensuring continuous operation and safety on both the runways and in the tunnels, the monitoring solution needed to be innovative, customised, and highly reliable. The fully automated Leica Geosystems monitoring system met these requirements with a combination of advanced geodetic sensors, robust connectivity, and an independent power source tailored to the site’s constraints.

The Leica TM60 monitoring total station was core to the system - a high-precision instrument capable of collecting settlement data in prism-free mode. Mounted on a specially constructed pillar, the TM60’s durable design – including IP65-rated weather protection and piezoelectric ceramic drive technology – made it well-suited to withstand the high temperatures and strong winds typical of the airport environment, all while maintaining exceptional performance.

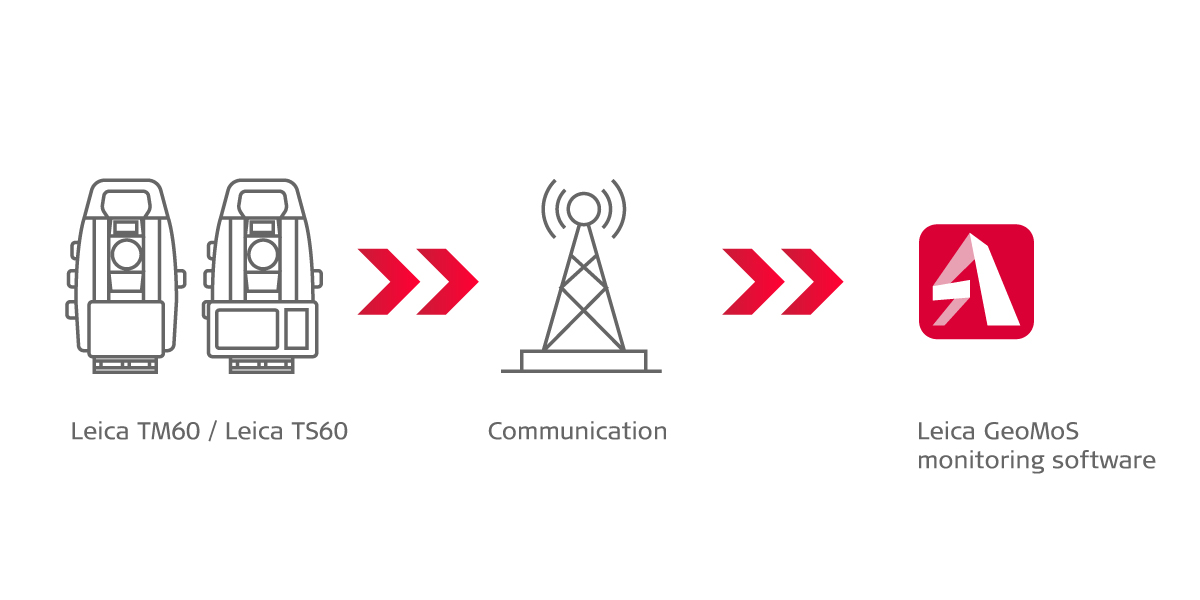

The TM60 was controlled by Leica GeoMoS Monitor software, which enabled fully automated and remote data collection. A solar panel and battery system provided a self-sustaining power source, ensuring uninterrupted operation in the challenging outdoor conditions. Backup batteries were also installed to maintain functionality during periods of low sunlight, further enhancing the system’s reliability.

Despite the complexity of the project, the system’s streamlined setup minimized disruption to airport operations. All equipment was installed and configured in just one day. Designed to operate autonomously for an estimated one-year period, the system was ready to deliver continuous, real-time ground settlement data throughout the construction process.

Data in action: monitoring settlement trends

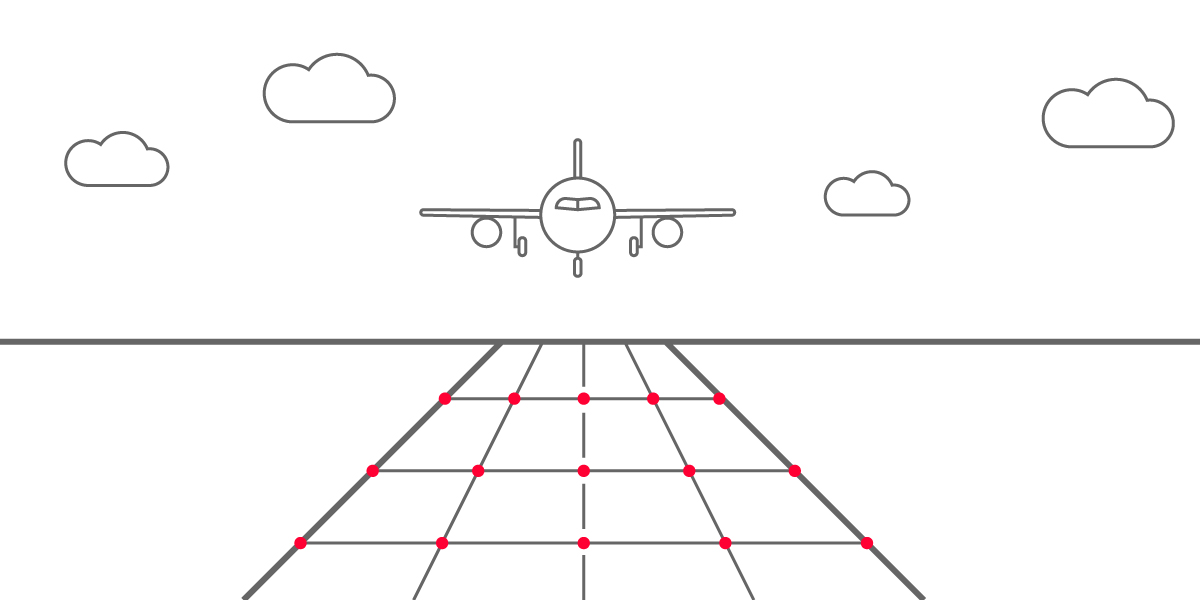

Once operational, the system began collecting millimetre-level settlement data. By measuring reflectorless points in a grid pattern on the runway surface, the team could monitor whether each measured point maintained the same vertical height over time. This was crucial because any formation of low spots on the runway not only indicated potential subsidence below but also created areas where water could accumulate, posing grip and stability risks for aircraft.

GeoMoS Monitor software controlled automated measurements taken every two hours at predefined points along and perpendicular to the tunnel axis, ensuring comprehensive coverage of the monitored area. Data was transmitted wirelessly from the TM60 via a 4G/LTE network, eliminating the need for on-site data retrieval and enabling remote monitoring.

All measurements were stored in a centralised database, where users could remotely access and analyse the data. Using GeoMoS Now’s advanced visualisation tools, the project team could generate elevation displacement maps and trend analyses, offering valuable insights into ground movement patterns over time.

To ensure safety, the system was configured by users to trigger alerts if settlement exceeded predefined thresholds. These alerts allowed the team to take immediate action, preventing potential hazards and safeguarding both the construction project and ongoing airport operations. This proactive monitoring approach provided a reliable foundation for maintaining safety in a dynamic and high-stakes environment.

Measuring reflectorless points in a grid pattern on the runway surface

Supporting progress through precision monitoring

The successful implementation of this monitoring system at Guangzhou Baiyun International Airport highlights more than just technical achievements – it demonstrates the critical role of innovation in safeguarding infrastructure in complex and high-stakes environments.

With its fourth runway now operational and its third terminal on track for completion in 2025, the airport continues to reinforce its position as a vital hub in China’s transportation network.

By enabling continuous monitoring during both construction and airport operations, Leica Geosystems’ monitoring solutions played an important role in supporting this transformative project. The system not only supported the safety of the ongoing work but also contributed to the airport’s broader mission of facilitating reliable and safe transportation for millions of passengers and goods each year.